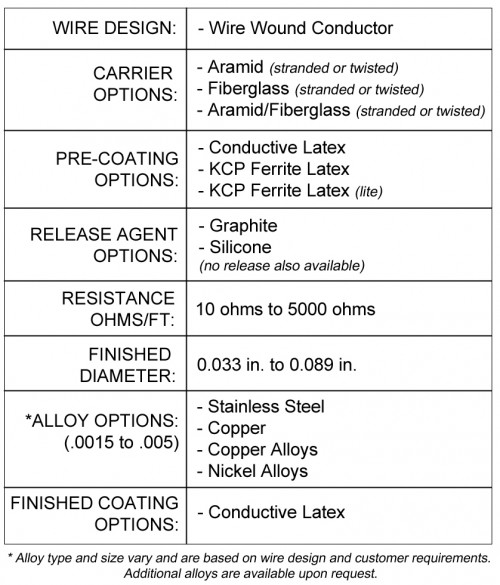

Some of the most popular conductors used in ignition wires are wire wound conductors. Wire wound conductors are constructed by winding a fine alloy wire around a carrier typically made up of aramid, fiberglass, or a combination of both. The carrier can be twisted or stranded, be pre-coated with conductive latex or be pre-coated with KCPs special ferrite-loaded latex to make magnetic (reactive), depending on your requirements. Wire wound conductors are very reliable, do not reduce energy to the spark plugs, and have excellent heat-resistant properties. Resistive levels of wire wound core are made to order from 10 ohms per foot to 5000 ohms per foot, depending on your specific needs. See the table below for some of the more popular options in wire wound constructions. Other options not listed my be available upon customer request.